Swaged Wire Rope Fittings & Wire Rope Assemblies

Swage Wire Rope Fittings & Assemblies.

Wire rope is extensively used in construction, marine and architecture. Stainless steel wire rope, when used in the right way, offers strength and long-lasting beauty all in one, and it is the end connections and joints of the stainless steel wire rope system where all the difference can be made in terms of appearance and strength.

Swaging of fittings onto stainless steel wire rope is the process where the end of the wire rope is pushed into a hole or bore in the swage fitting, and then the swage fitting is mechanically squeezed onto the wire rope, ideally with such force that a good structural connection is made. The wire rope and swage fitting are carefully chosen so that the bore of the swage fitting is just large enough to freely push the wire rope into it, and then in the swaging process the diameter of the swage fitting is reduced to create an interference fit between the swage fitting and the wire rope. Once the swaging has been completed, we end up with a permanent and irreversible connection between the fitting and the wire rope, so it is important that the specification (type of stainless steel wire rope, diameter of wire rope, type of fitting including thread specification, and overall length) are fully understood and agreed before swaging.

A preferred method of swaging is to pass the swage fitting and wire rope together through a pair of roller dies which squeeze the swage fitting into a smaller size as the assembly rolls through the dies, the forces involved are high and usually make use of a hydraulic system. This is how we perform our in-house swaging of stainless steel wire rope assemblies at Architectural Stainless Fittings. After swaging, the change in diameter of the swage fitting can be checked against recommendations to ensure that the swage has been completed properly. When done in this way the swaging process an achieve a strength not too far below the breaking strength of the wire rope itself.

Wire Rope Types

Wire rope comes in different types (constructions / layups), as well as the chosen material grade and overall diameter, the construction of the wire rope has an influence on its overall feel and behaviour. There are many specialist constructions of wire rope, but here will briefly cover some of the more commonly available ones.

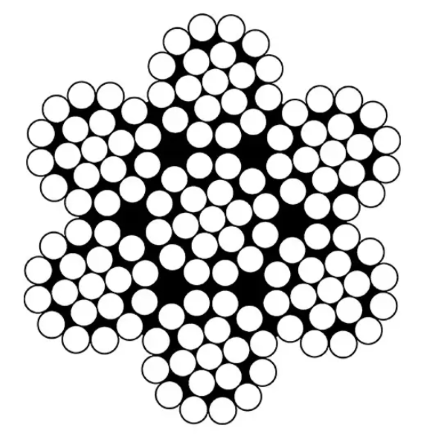

7x19 Wire Rope Construction

This is a flexible construction consisting of seven main bundles, a central bundle surrounded by 6 further bundles. Each of the bundles contains 19 stands of wire. This configuration gives a resulting wire rope which is flexible enough for most uses, and allows the end of the wire rope to be made into a loop, either with a securing clamp or with a securing crimp fitting.

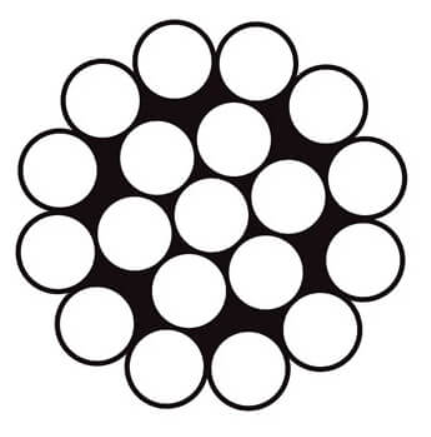

1x19 Wire Rope Construction

This is a stiffer construction of wire rope and consists of 19 strands in total. It has quite a lot stiffer (less bendable) feel than the 7x19 and less suitable for bending into a small radius. In some applications the stiffer feel of the wire rope is an advantage, such as balustrade wire rails, where a stiffer feel (needing less tensioning) gives a better feeling to the touch. Another difference is the 1x19 wire rope construction, particularly stainless steel 1x19 wire rope is that is has a more shiny ‘sleek’ appearance which might be more appealing for certain architectural uses.

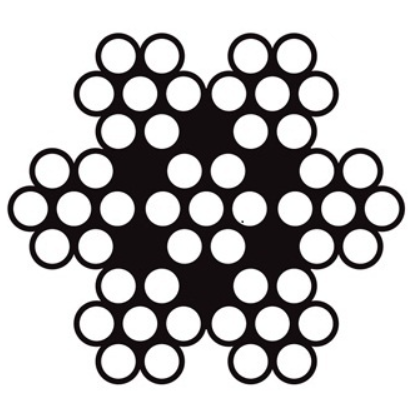

7x7 Wire Rope Construction

In-between the 7x19 and 7x7 constructions mentioned above we have the 7x7 construction of wire rope which consists of 7 bundles of 7 strands of wire. This gives an intermediate level of stiffness or bendability compared to the other constructions.

Stainless Steel Swaged Wire Rope Assemblies

A swaged wire rope assembly consists of the wire rope (in our case 316 stainless steel wire rope) and a fitting on each end – again in our case a 316 stainless steel fitting usually. In all cases though the purpose of the end fitting it to provide a connection to something else. Common uses of wire rope assemblies include the following:

- Stay’s for stabilising tall structures (eg masts, industrial chimneys, antennas)

- Tension ‘rails’ for balustrades, usually guided through some main structural framework the wire rope assemblies act is intermediate rails (horizontal) or spindles (vertical)

- Lifting strops and lifting equipment. At Architectural Stainless Fittings we do not provide wire rope assemblies for lifting operations (lifting safety rated). For wire rope assemblies rated for lifting safety it is recommended to work with a specialist company for lifting safety.

- Display shelving, shop-front displays, interior shop display hanging arrangements.

Swaged End Fitting / Tensioning Screw On Balustrade Rail

The simplest and most common swage fittings for stainless steel wire-rope assemblies are threaded terminals, either ending with a female thread or male thread. These give a simple and versatile way of connecting to various other fittings, such as turnbuckles and pelican hooks. Other types of swage fitting are fork-end swage fittings or eye end fittings, the fork-end terminals usually come with a clevis pin and securing ring pin to give all that is needed to connect to various other standard or bespoke brackets.

If you are in need of a stainless steel wire rope assembly please get in touch with us by email or phone.